Are Dynamic Air’s pneumatic conveying systems suitable for conveying materials that are high-temperature or corrosive?

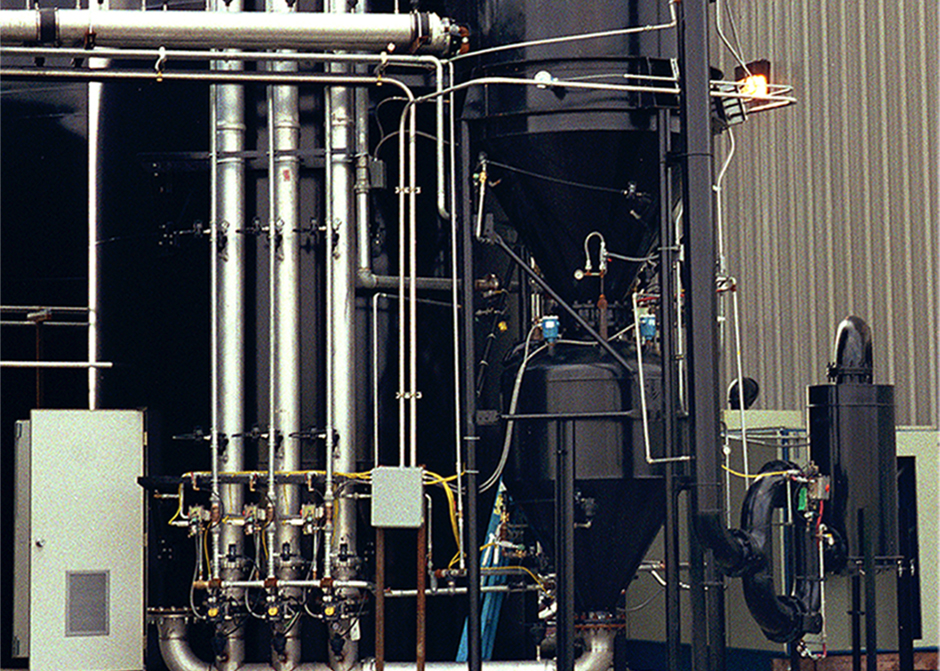

Yes, we engineer high-performance pneumatic conveying systems using heat-resistant and corrosion-resistant materials for challenging applications in industries such as metallurgy, waste-to-energy, and industrial recycling.

Are Dynamic Air’s process solutions suitable for conveying materials that are hazardous or toxic?

Yes, this is an important reason to select Dynamic Air. Materials that are toxic to people, or toxic to the environment need to be handled in a dust-tight process so that the danger inside the process doesn’t affect the people and the environment on the outside of the process. And for flammable or explosive materials, controlling the process environment with an insert gas, such as nitrogen, eliminates the possibility of disaster.

We have a fragile bulk material that needs to look the same at the end of the process as it did at the beginning. How do we solve this problem?

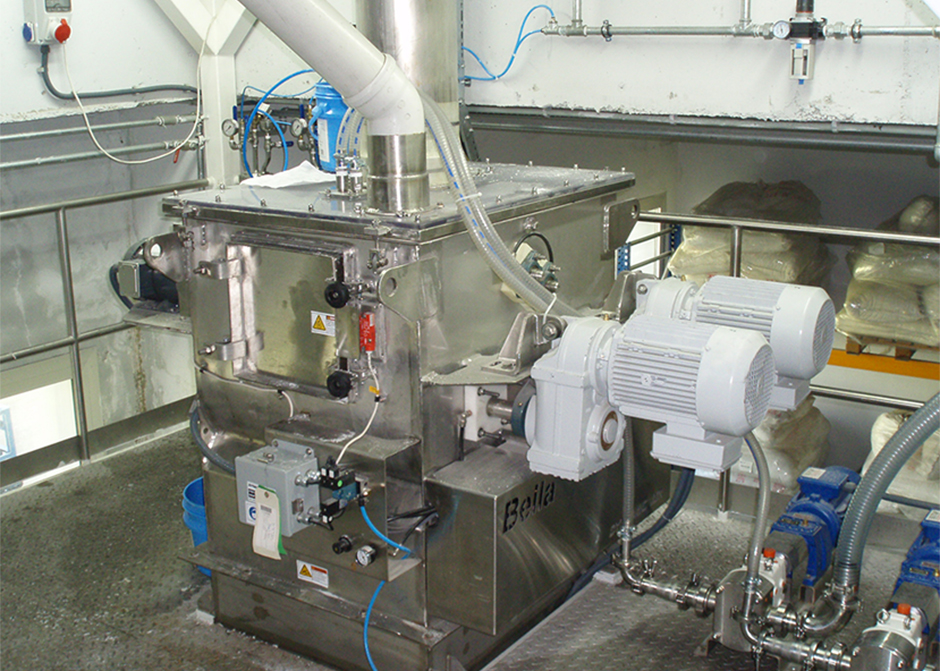

This is where Dynamic Air’s gentle handling approach pays off. It does you no good to produce a perfect granule only to have it turned to dust by the time you package it. Dynamic Air has provided successful processes for some of the most fragile dry bulk materials, such as granulated sugar, pelletized carbon black, breakfast cereal, spray-dried milk powder and more. And we have a test facility where we can demonstrate our process with your material. It’s not just theory, we prove it.

But what about abrasive bulk materials? Can you really convey abrasives in a pneumatic conveying system?

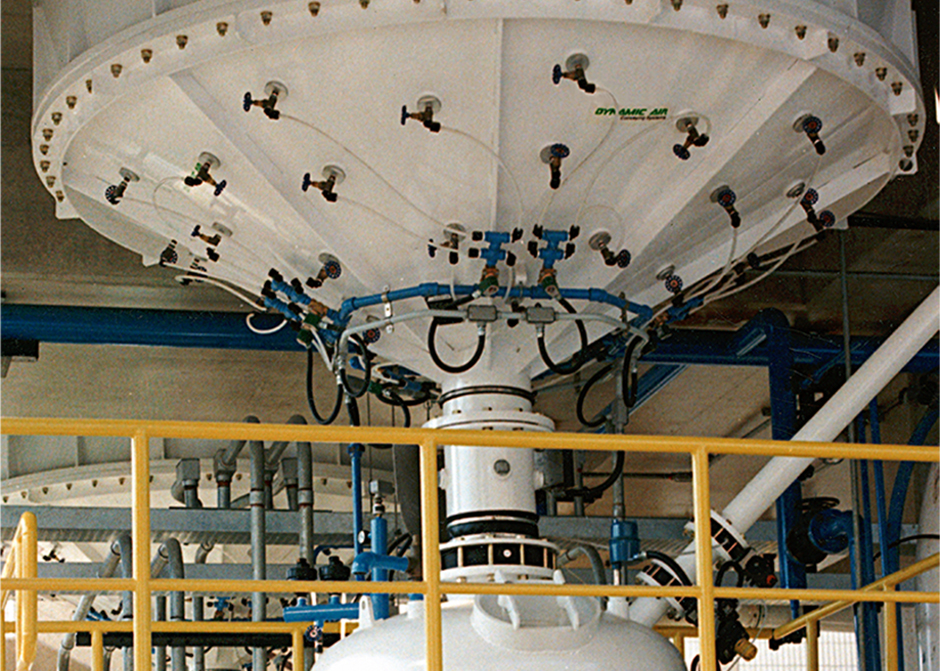

Dynamic Air started in 1969 with an invention, the Dyna-Chek booster fitting. This invention was developed specifically for dense phase conveying of abrasive foundry sand. The next industry we applied this technology to was glass batching plants. These are two of the most abrasive materials due both the hardness and the sharp edges on the particles. Now we are on our 5th generation of this invention. So, yes, our systems are especially suited for abrasives. And by the way, some of these foundry sand and glass plant systems are still operating after more than 50 years.

How does Dynamic Air customize conveying systems for niche industrial applications?

We’ve been doing this since 1969, and because of our vast experience, we most likely have already developed the specific solution you need. And if we haven’t, our experience with similar materials and processes gives us a leg up on developing your custom solution. Dynamic Air offers tailor-made pneumatic conveying solutions based on material characteristics, space constraints, and process integration needs. Whether it’s handling fine powders, abrasive bulk solids, or fragile materials, we engineer systems for optimal energy efficiency and system performance.

What makes Dynamic Air a trusted partner for specialized pneumatic conveying solutions?

Since 1969, Dynamic Air has been providing proven pneumatic conveying and process system solutions, offering expert engineering and global service support. Our solutions are designed for maximum uptime, low maintenance, and consistent material flow, no matter the industry.

What industries use Dynamic Air’s pneumatic conveying systems beyond food, plastics, and chemicals?

This list would extend into the hundreds. Dynamic Air’s pneumatic conveying systems are also widely used in mining, pharmaceuticals, tire, glass, cement, metals, energy production, and environmental processing. These systems offer efficient and reliable bulk material handling solutions for nearly any dry bulk material in specialized sectors.