Why Dense Phase Pneumatic Conveying Makes Sense for Materials that Compact

Pneumatic conveying systems are an indispensable part of many industries, efficiently transporting bulk materials through pipes using air pressure. However, when it comes to conveying materials that tend to compact, many systems struggle. It’s only natural to wonder: if air pressure is used to move a material, won’t it just compact and clog the pipe? It’s a reasonable concern, but fortunately, the right technology can overcome this challenge.

When dealing with compactable materials, Dynamic Air’s proprietary DC-5 air saver system can achieve conveying success

Let’s dive into how this innovative technology works and why it’s a game-changer for materials that tend to compact during the conveying process.

Why Dense Phase Pneumatic Conveying?

With Dense Phase Pneumatic Conveying, materials are moved through the pipeline at lower velocities and higher air pressures. It is the ideal solution for abrasive or fragile dry bulk materials, for long distance conveying, for high-rate applications where power efficiency is important, for processes where reliability is paramount, and for dry bulk materials where controlling the process environment (for example the humidity) is important. But for materials that tend to compact, many users are wary of dense phase conveying due to plugging concerns.

By utilizing dense phase conveying, you minimize the wear and tear on the system (or the material particles) while ensuring a more stable and controlled movement of the material. The reason for this is because the conveyed material is moving through the convey pipe in dense slugs, reducing the percentage of material that comes in contact with the convey pipe. The material in the middle is protected. The concern is with materials that easily compact – such as mixed batches of coarse-to-fine materials, materials with subangular shapes, and materials with a wide size distribution.

The Challenge of Compactable Materials

Pneumatic conveying is most efficient when it moves materials that flow freely through pipes. However, materials that tend to compact, like those just mentioned, pose unique problems. These materials can lead to blockages, slowdowns, and inefficiencies in the system.

For instance:

- Refractory batches that are designed to be pressed into bricks can be dense and heavy, making them difficult to convey using traditional systems.

- Quicklime, with its wide particle size distribution, can create a mix of fine and coarse particles that don’t move as easily through pipes.

- Foundry green sand, with its unpredictable flow characteristics, can become sticky and clog pneumatic systems.

- Sweeteners and sugars, such as Sorbitol and Mannitol, often have varied particle sizes that can cause the material to pack together.

- Candy batches, like SweetTarts or Pez, are compressed into pellets and can be prone to compaction during conveying.

In these cases, traditional pneumatic conveying systems might not work because the material can compact under pressure, creating blockages that halt the process and cause operational delays.

The unique design provided by Dynamic Air solves this problem with our DC5 air saver technology:

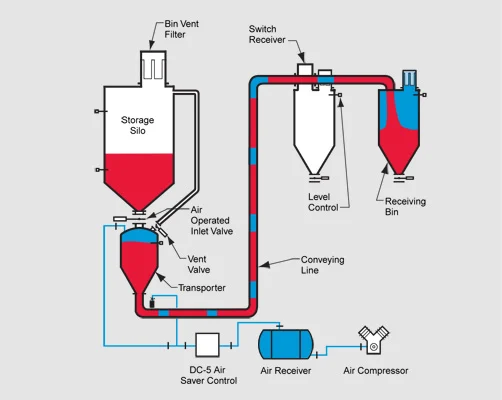

HDP 3000 Conventional Concept dense phase pressure system

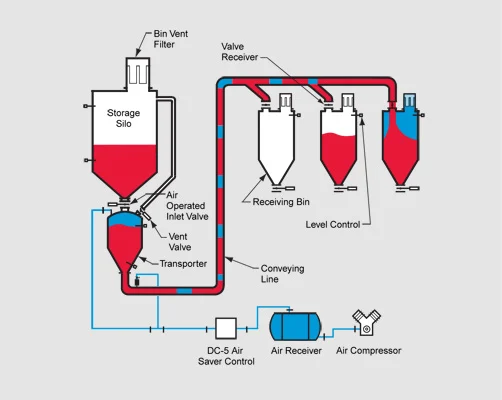

HDP 4000 Full Line Concept dense phase pressure system

Enter Dynamic Air’s HDP Conveying Systems with DC-5 Air Saver Technology

While it’s true that compactable materials pose challenges for standard pneumatic systems, Dynamic Air’s HDP Conveying Systems, equipped with our DC-5 Air Saver Technology, offer a powerful solution. These systems are designed specifically to tackle the issues presented by compactable materials, ensuring that the process continues smoothly without the risk of blockages.

The DC-5 Air Saver Technology is an innovative feature that makes this possible. Instead of relying on a constant flow of air that might cause materials to compact, the DC-5 system continuously applies air pressure precisely where it’s needed, at the right time and in the right amount. This strategic application of air pressure helps keep the material moving and prevents it from plugging.

How Does the DC-5 Work?

The key advantage of DC-5 technology lies in its ability to apply air pressure dynamically throughout the entire conveying system. Rather than using more compressed gas to dilute the conveying process, the DC-5 applies air at the precise locations where it’s needed. This helps to maintain material flowage throughout the conveying process.

This “air leverage” across the entire pipeline ensures that materials flow smoothly without the risk of blockages, even when they’re compactable. The DC-5 system essentially acts as a safeguard, preventing the material from plugging and allowing it to continue moving with minimal disruption.

Additional Benefits of DC-5 Air Saver Technology

Besides preventing blockages, there are several other advantages to using DC-5 Air Saver Technology in your pneumatic conveying system:

- Reduced Energy Consumption: The DC-5 system optimizes air pressure application, which means it doesn’t waste energy. It provides air only where it’s necessary, making your system more energy efficient.

- Fewer Maintenance Issues: Because the system minimizes compaction and reduces the risk of clogs, there’s less strain on your equipment. This leads to fewer breakdowns and lower maintenance costs.

- Improved System Reliability: With consistent, controlled airflow, your pneumatic conveying system is less likely to suffer from shutdowns caused by blockages. Over time, this increases the uptime of your process.

- Flexibility: Whether you’re handling fine powders, dense granules, or irregular materials, the DC-5 technology adapts to your specific needs, ensuring efficient and reliable material handling across a wide range of industries.

Say Goodbye to Blockages and Slowdowns

Pneumatic conveying doesn’t have to be a logistical challenge, even when dealing with compactable materials. With Dynamic Air’s HDP Conveying Systems and DC-5 Air Saver Technology, you can ensure smooth operations, reduce blockages, and minimize downtime. Whether you’re dealing with dense powders, granular substances, or irregularly shaped materials, our advanced systems are designed to keep your processes running efficiently and reliably.

Ready to Learn More?

At Dynamic Air, we’re not just focused on moving materials; we’re dedicated to moving them the right way, with precision, reliability, and efficiency.

Reach out to us today to learn more about how we can help streamline your material handling process.

Let us help you get the job done, no matter how tough the material.

Quick Links to our State-of-the-art Dense Phase HDP Pressure Systems:

HDP 3000 Conventional Concept™

Let’s Find the Right Solution for You

Contact usPartner with Dynamic Air, the industry leader in providing reliable, innovative solutions. Our team of experts is ready to understand your unique requirements and design customized solutions tailored to your specific needs, whether it’s pneumatic conveying, equipment manufacturing, or other material handling challenges. Experience the Dynamic Air difference and unlock the potential of seamless material flow, enhanced efficiency, and optimized productivity. Contact us today to discuss your project.