Experience The Epitome Of Innovation At Dynamic Air's State-Of-The-Art Test Facility

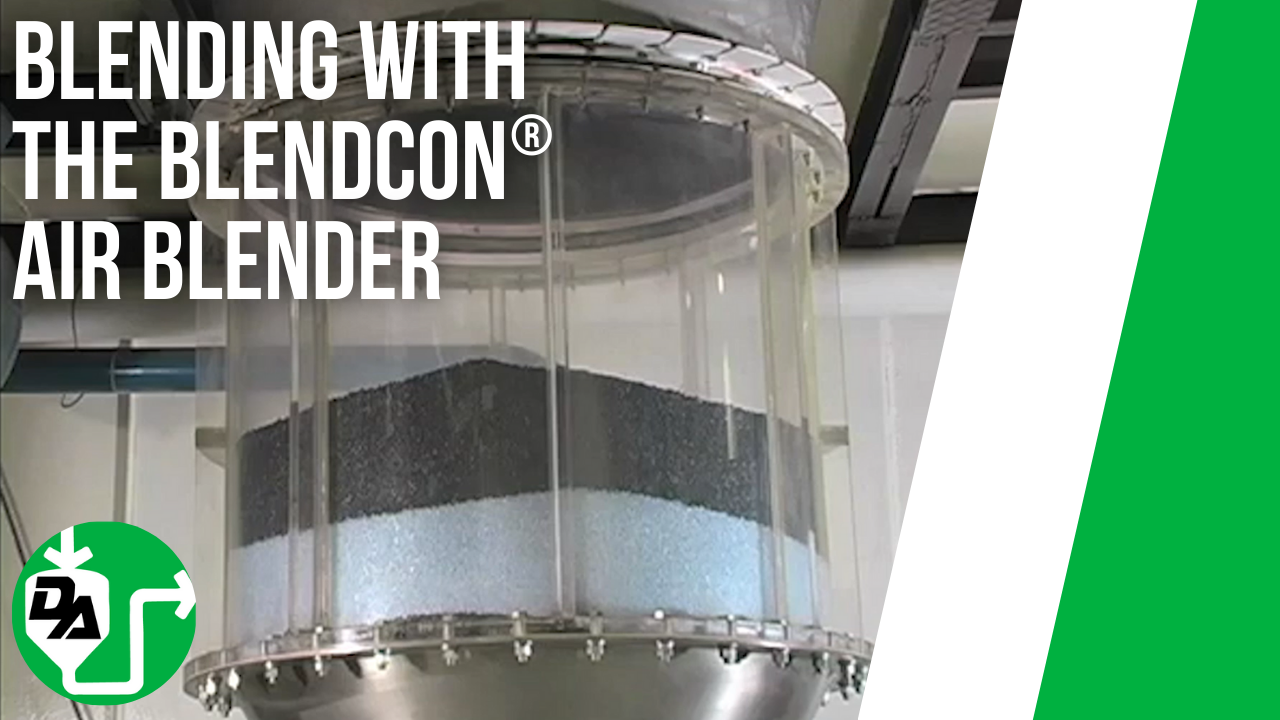

Step into Dynamic Air’s state-of-the-art test facility, a dedicated space for our customers and potential partners to experience the epitome of innovation. Here, we believe in a precise sequence: Know the material, understand the process, and then master the equipment. By embracing this philosophy, we ensure each system is meticulously tailored to suit your material’s specific needs. Dive deep into the world of pneumatic conveying, blending, and more, guided by cutting-edge technology and unparalleled expertise.

In-Depth Testing Capabilites

The Dynamic Air test facility isn’t just another lab; it’s a beacon of comprehensive solutions. We offer:

Materials Handled

Every dry material undergoes rigorous analysis to pinpoint its exact handling characteristics and performance values. Through state-of-the-art tests, we scrutinize hygroscopic effects, buildup tendencies, degradation issues, and much more. It’s our commitment to detail that allows us to provide insights into dust filtration requirements, optimum pressure needs, filling times, material-to-air ratios, and many other critical data points.

| Material Name | Bulk Density | Particle Size | ||

| (Tested and conveyed at Dynamic Air) | lb/cu ft | g/cm3 | inches | millimeters |

| Paper Pulp – PWT Fiber | 17 | 0.272 | 0.66670 | 16.9342 |

| Paper Pulp Fines | 21 | 0.337 | 0.66670 | 16.9342 |

| Paper Pulp Pelletized #2 | 34 | 0.545 | 0.50000 | 12.7000 |

| Paper Pulp Pelletized | 37 | 0.593 | 0.50000 | 12.7000 |

| Paper Pulp Pelletized Fine | 43 | 0.689 | 0.66670 | 16.9342 |

| Paraffin Wax Prills | 31 | 0.497 | 0.05560 | 1.4122 |

| Peanuts Roasted Halves | 28 | 0.449 | 0.75000 | 19.0500 |

| Peanut Parts & Fines Roasted | 34 | 0.545 | 0.50000 | 12.7000 |

| Peanut Halves | 36 | 0.577 | 0.50000 | 12.7000 |

| Peanuts Roasted Chucks | 39 | 0.625 | 0.12500 | 3.1750 |

| Peanuts Raw Splits | 39 | 0.625 | 0.22200 | 5.6388 |

| Peanuts – Halves | 40 | 0.641 | 0.50000 | 12.7000 |

| Peanuts Raw Whole | 41 | 0.657 | 0.75000 | 19.0500 |

| Peanuts Roasted Halves | 42 | 0.673 | 0.50000 | 12.7000 |

| Peanut Splits Roasted | 42 | 0.673 | 0.62500 | 15.8750 |

| Peanut Chocolate Covered | 48 | 0.769 | 0.75000 | 19.0500 |

| Peas Whole | 40 | 0.641 | 0.25000 | 6.3500 |

| Pentaerthyritol | 38 | 0.609 | 0.00750 | 0.1905 |

| Pentalyn Resin – H/Dilute | 39 | 0.625 | 0.37520 | 9.5301 |

| Percarbonate (PC3) | 68 | 1.090 | 0.00400 | 0.1016 |

Data-Driven Excellence

Harness the power of the most advanced testing capabilities, ensuring not just accuracy, but a deep dive into material intricacies. Whether it’s understanding respective velocities, equipment performance criteria, or air volume requirements, our data-driven approach paves the way..

Unlock The Future of Material Handling

Ready to dive deep into the epitome of material handling testing? Schedule a visit to our facility and immerse yourself in unparalleled innovation and expertise, watching your material’s journey be analyzed, optimized, and perfected by the team at Dynamic Air. Reach out to us today!